CONTUR Dialog HS-63/HS-71 Cycle lathes

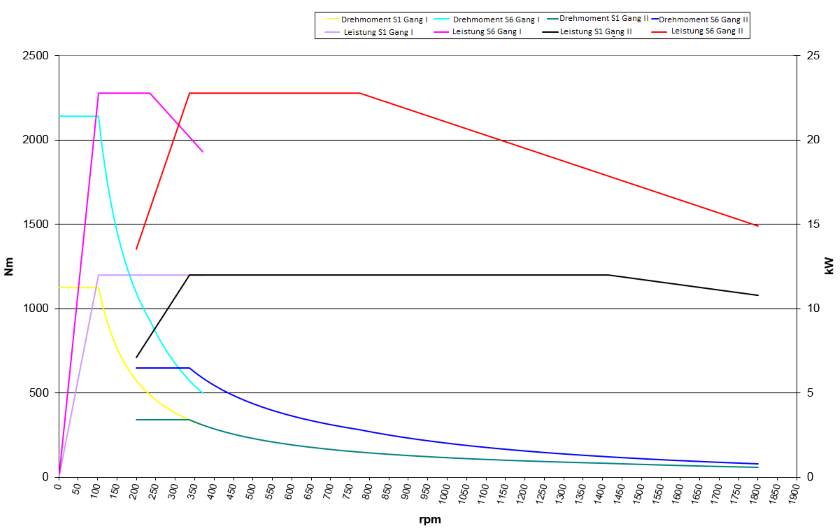

The CONTUR Dialog HS-63 / HS-71 are the perfect solution for economical single part and series production. Two gear stages ensure high torque even at low speeds. The gear stages are switched manually, optionally, and automatically. The machine bed, guide systems and electrical, and electronic equipment are designed for high demands in terms of performance and precision. The high number of more than 200 satisfied Dialog HS users in Germany confirms this.

Special Features:

- Control: SIEMENS 840D SL with ShopTurn and single cycles (manual machine)

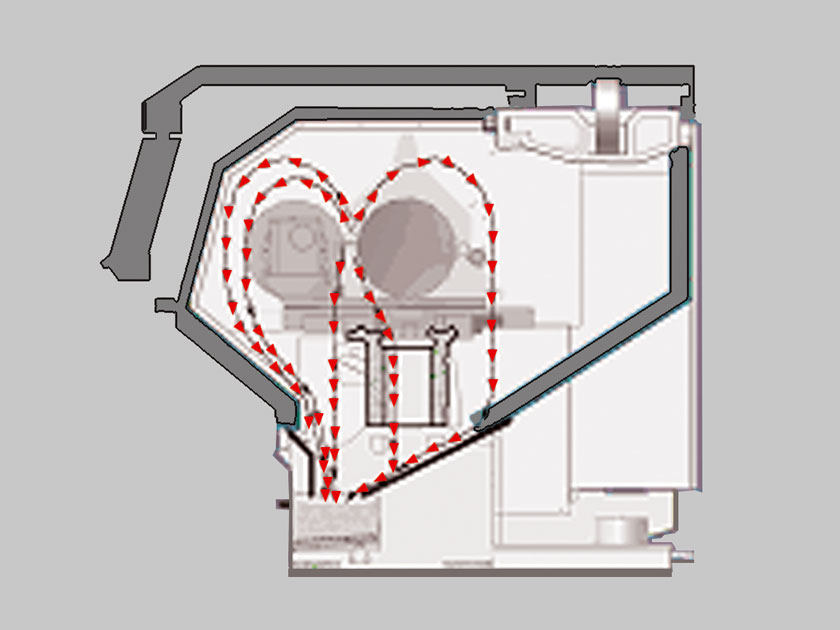

- wide and heavily ribbed double-walled bed for high rigidity

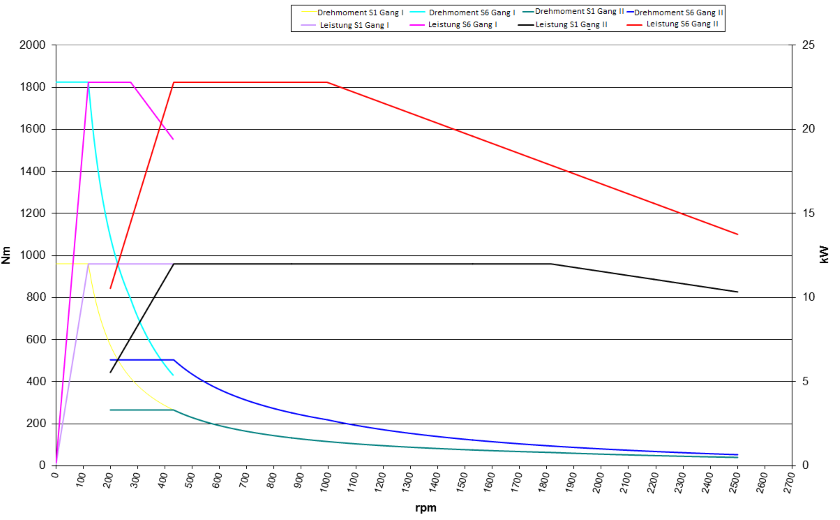

- 2140 Nm max. Spindle Torque

- 20 kW drive power with automatic 2 gear stages

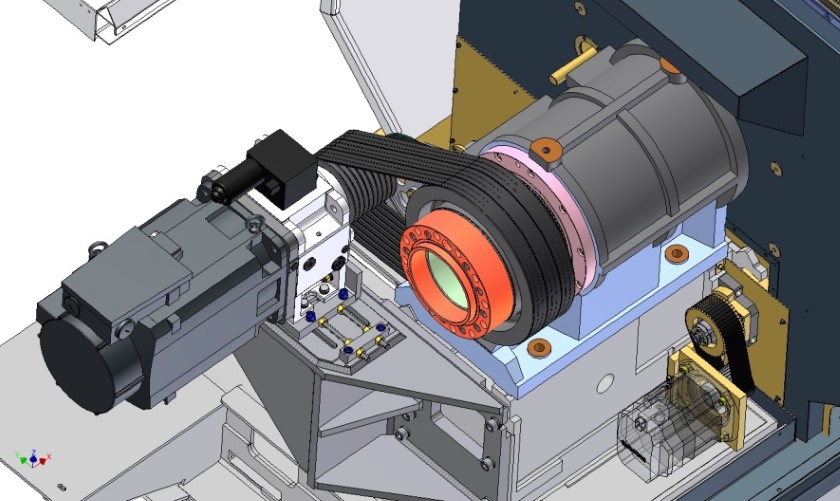

- very rigid bearing of the main spindle from a combination of ball bearings and cylindrical roller bearings

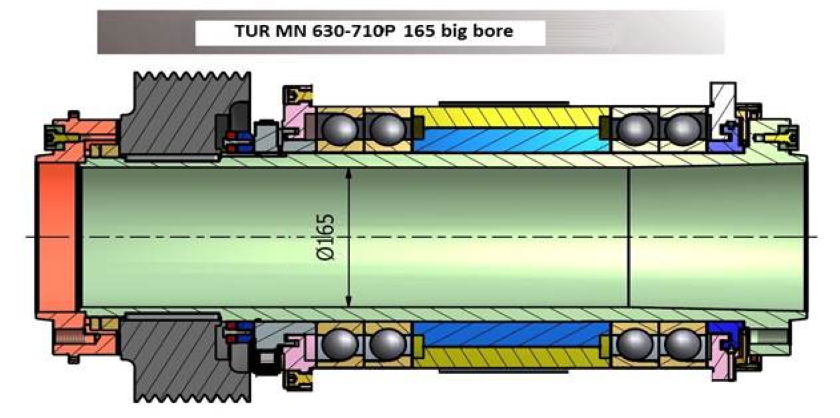

- large spindle bore with 140 mm (larger bore with P-model)

- Double prismatic guide and Turcite-B coating

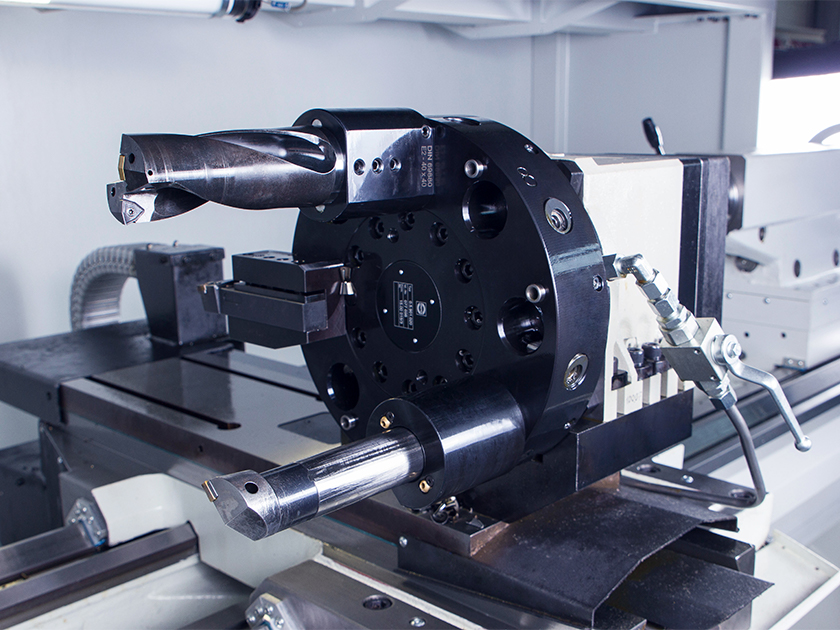

- Option: tool turret with or without driven tools

Special versions P-Modell:

P-model: also has larger spindle bores of Ø 165 mm or Ø 190 mm. In contrast to the standard HS-63 / HS-71, the gear arrangement has been changed in the P- model. A motor gear (planetary gear) with a reduction of 1: 4 is used for the high spindle bores.

The spindle is equipped with two (Ø165mm) or three (Ø190mm) angular contact ball bearings at the front and two angular contact ball bearings at the rear. By using large angular contact ball bearings, a high speed of 1800 rpm is achieved with high precision, high load capacity, and perfect surface quality.

| Technical Data | HS-63 | HS-71 | P-Performance | ||

|---|---|---|---|---|---|

| Swing Diameter above Bed | mm | 630 | 710 | ||

| Swing Diameter above Sliade | mm | 370 | 450 | ||

| Center Distance | mm | 1000 - 6000 | 1000 - 6000 | ||

| Spindle Speed Range | rpm | 2500 | 2500 | 1800 | |

| AC Asynchronous Motors (S6) | kW | 20 (30) | 20 (30) | 13 (18) | |

| Max. Torque | Nm | 2140 | 2140 | 1625 | |

| Spindle Bore | mm | 140 | 140 | 165 or 190 | |

| Spindle Nose | mm | D1-11 | D1-11 | Direct 11 / Direct 15 | |

| Net Machine weight approx. | kg | 5100 (1m Center Distance) bis 7500 (4m Center Distance) | 5300 (1m Center Distance) to 7700 (4m Center Distance) | ||

| Technical changes and errors exempted |

Further informations